Item | Parameters | ||||

Machine model | MS-430AC | MS-540AC | MS-650AC | MS-860AC | MS-1080 |

Worktable stroke(X,Y,Z) | 400×320×300mm | 500×400×300mm | 600×500×400mm | 800×600×400mm | 800×1000×400mm |

Worktable size (W×D) | 760×580mm | 820×620mm | 1020×680mm | 1210×880mm | 1300×900mm |

The oil tank size (W*D*H) | 920×680×400mm | 1010×740×400mm | 1200×820×400mm | 1350×930×400mm | 1600×1100×400mm |

X-Axis travel | 400mm | 500mm | 600mm | 800mm | 1000mm |

Y-Axis travel | 320mm | 400mm | 500mm | 600mm | 800mm |

Z-Axis travel | 300mm | 300/400mm | 400mm | 400/500mm | 400/500mm |

Travel U、V | 60×60mm,100×100mm | ||||

Max. taper angle | Optional±6~15 degree / 100mm thickness | ||||

X,Y axis motor | AC servo motor | ||||

U,V axis motor | Stepper motor(Optional servo motor) | ||||

Z-axis control | Electric adjust | ||||

Wire guide frame | Adjustable | ||||

Wire Speed | 1.18-11.18m/s | ||||

Diameter of wire | Dia.0.1~0.22mm | ||||

Wire tension | 10-30N | ||||

Positioning accuracy | ±0.01/500mm(GB/T 7926-2015) | ||||

Repeatable accuracy | ±0.005mm(GB/T 7926-2015) | ||||

Max. Cutting Currrent | 10A | ||||

Max cutting speed | ≥300mm²/min(it is different for different material and thickness) | ||||

Best Surface Finish | Multi-cut Ra≤0.85μm(it is different for different material and thickness) | ||||

Precision machining | Multi-cut(Octagon±0.006mm,Taper±0.01mm ) | ||||

Filters water tank | Optional 80L/130L | ||||

Control box dimension | 600×680×1860mm | ||||

Control box weight | 140kg | ||||

Machine dimension (W×D×H) | 1650×1250×2100mm | 1700×1400×2100mm | 2050×1680×2100mm | 2200×1800×2200mm | 2500×2000×2300mm |

Machine weight | 1450Kg | 1650Kg | 1900Kg | 2650Kg | 3400Kg |

CNC System | |||||

Operating system (OS) | Windows | ||||

CNC Control system | Autocut | ||||

Drawing Programming system | NCCAD,AutoCAD | ||||

Hardware Configurations | P4 or better, Standard keyboard and mouse, with 17"LED | ||||

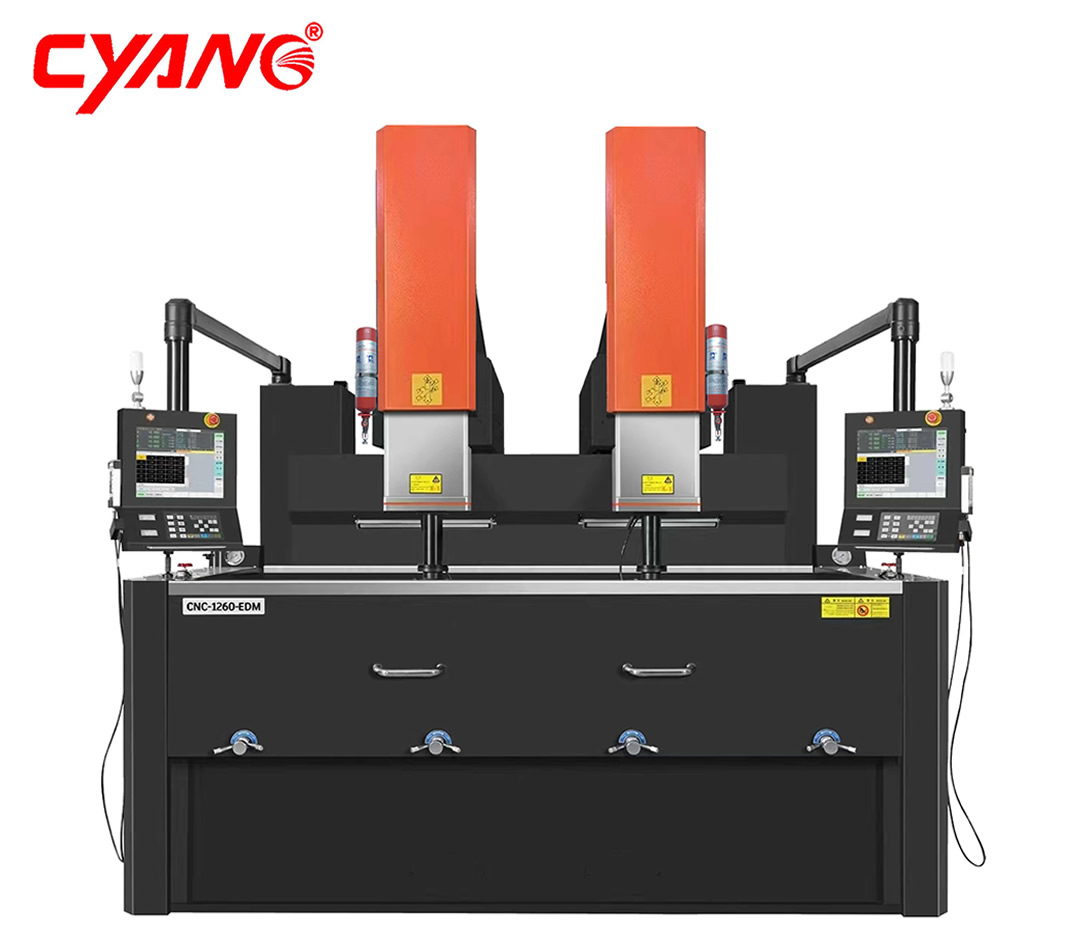

Control method and axis | 4 axis Control simultaneous program | ||||

Single pulse advancing accuracy | 0.001mm | ||||

Data Port | USB, LAN | ||||

File formats supported for import | DXF,DFT,DAT | ||||

Programming Code | 3B/ ISO/G code | ||||

Menu Language | Chinese/English/ Russian | ||||

Dimension | Metric/Inch | ||||

Power Supply | |||||

Power | 380V±10%,50/60±1HZ | ||||

Other power | 110~415V±10%,50/60±1HZ | ||||

Consumption | 2.5KVA | ||||

Working temperature | 10-35℃ | ||||

Relative humidity | 40%~80% | ||||

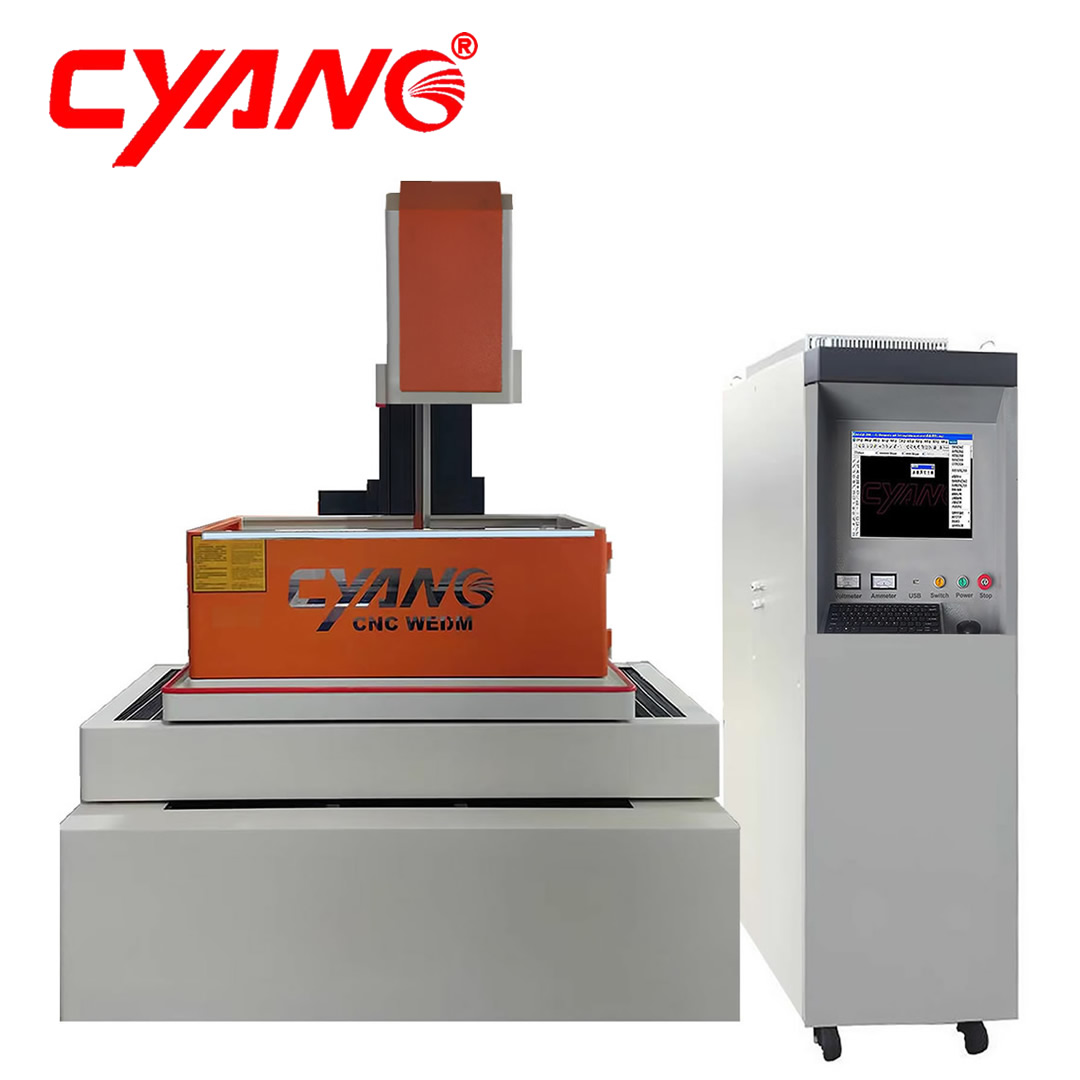

This type is popular machines.Machines are with servo motors , Affordable prices.

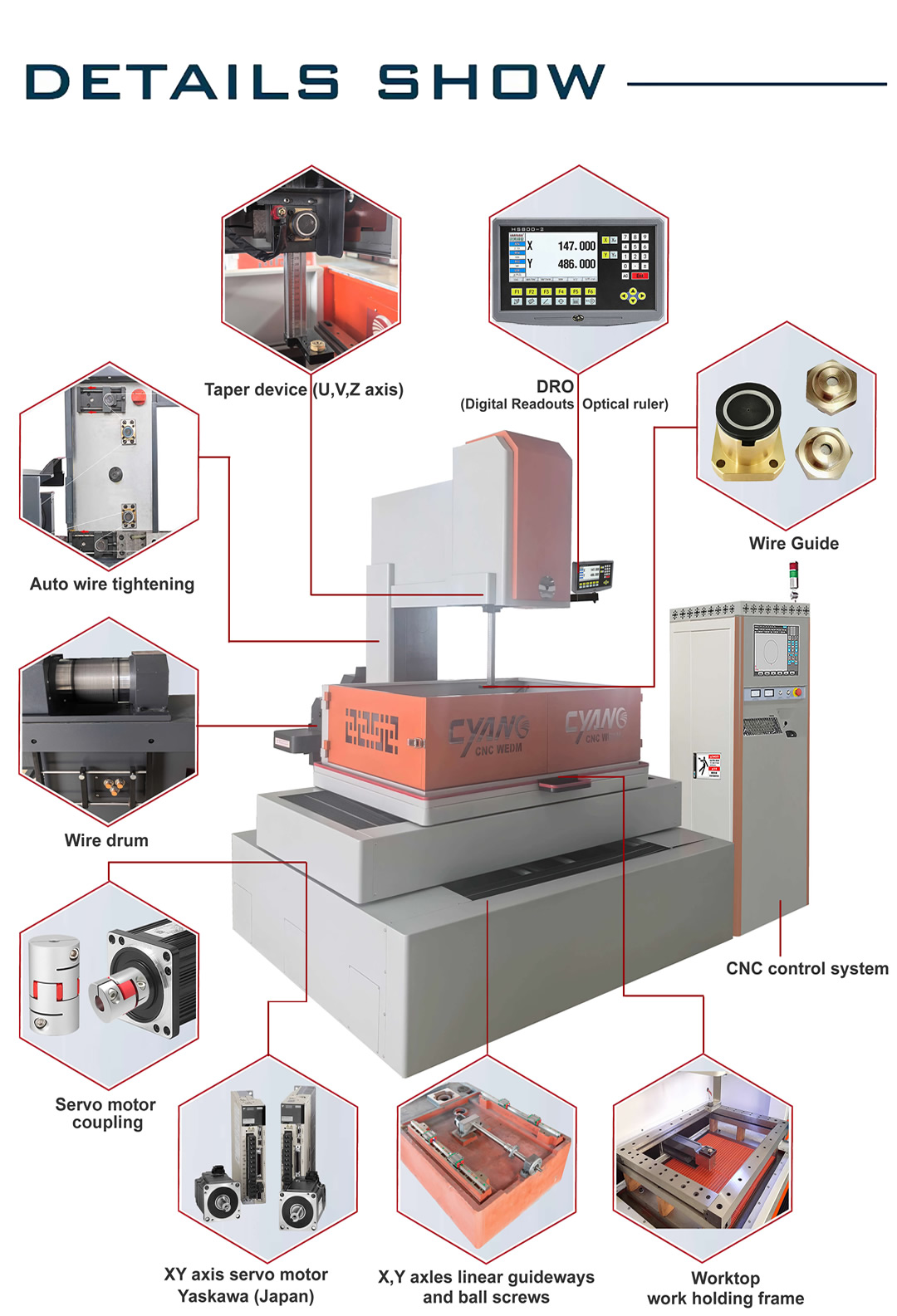

The Machine Body: Adopt the base of Meehanite cast iron (HT250), two aging treatment to eliminate stress and effectively inhibit the deformation of the machine tool.which makes the machine body of high load intensity and has ability to resist distortion.

Guideway and Ball Screw: Adopt Taiwan precision linear guideway and P3 grade double nut ball screw .

Structure of wire frame:The symmetric structure for the upper and down frame to keep the tension of moly wire within the scope of normal tension. So no matter thin or thick work piece, the moly wire is not easy to break down.

The wire winding and traveling system: Wire winding drum is made of special steel, which is more stable, anti-corrosion. converter control the running direction, Which can be used longer time, improve the precision, roughness and reduce the wire broken.

The Taper Cutting Mechanism: It's driven by two step-motors to realize U and V movement, which can make the 4 axis (X,Y,U,V) simultaneously movement.

The working table: The table is equipped with a movable modular clamping device that can be moved to multiple positions to achieve installation and clamping according to the actual situation of the workpiece.

Working area:The frame water retaining structure with a three-sided opening design can against splashing and dripping of cutting fluid,allows for unobstructed operation and loading/unloading of workpieces.

Working fluid tank:A large-capacity water tank, with a multi-stage circulation filtration system, and filtration accuracy of 0.01mm.

Control system

Ø Which integrates the program and control and based on Windows. This new designed Autocut software is the unique software for WEDM running on the condition of windows. It is use graphic drive technology and auto-program, user doesn’t need to contact the code, only need to set the processing technics for the graphic. meanwhile,support 3B and G code generated by other WEDM software.upgrade the efficiency of working, reduce the mistakes.

Ø Using the PCI slot controller card and the High-tech Industrial computer, which greatly enhanced the stability of control and greatly reduced the computer the failure rate.

Ø To achieve a fast and convenient computer communication network, through network technology, graphics, data and program transmission, can be directly controlled by the technical design department since the first establishment of a program.

Ø Embedded Control system can be smoothly connected with many design software such as AUTOCAD & etc. Fulfill integration of CAD/CAM.

Ø Adopt 4 axes linkage control technic to process taper workpiece. Process the top and bottom shaped taper conveniently, make the complicated processing easy and exactly.Process track with 3D designed.

Ø XY axis the drive motor be set at AC servo motor. The search function of mechanical origin enable the transmission screw pitch compensation, in order to greatly improve the positioning accuracy.

Ø With a large storage capacity database, which accumulated from many experiences. User can choose the suitable parameter according to deferent working conditions. Users can adjust machining parameters to establish a database at any time according to their own experience.

Ø Pulse power of the control parameters directly from the software to control and improve the ability of pulsed power output of the interference, thereby increasing the roughness of workpiece, reducing the loss of molybdenum wire, you can choose a variety of pulse waveforms for a variety of processing conditions, improve the cutting ability of the workpiece.

Ø Simplifies the operation buttons on the control panel, a large number of button functions directly controlled by software to achieve.

Autocut Software basic function

Ø Copyrighted Windows platform makes the system stable and reliable.

Ø A richly functional operating system

Ø Powerful technological parameter database.

Ø Equipped with a drawing board and automatic programming function, multiple CPUs enable simultaneous processing and programming.

Ø Coordinate system: absolute coordinate, incremental coordinate (relative coordinate)

Ø Functions of coordinate transforming, zoom in and zoom out, rotating and tracking display in real time

Ø Functions of interpolation of straight line and circular arc

Ø Function of processing different top and bottom shape

Ø Functions of short circuit and wire-break handling

Ø Functions of memorizing when power was cut and auto-stop after processing

Ø Functions of auto-edge position and auto-centering

Ø Function of auto-adding transitional arc (Arbitrary angle)

Ø Function of processing backward

Ø Functions of multi-cutting(Max. Cut 7 times)

Ø The X and Y axes can be freely swapped to adapt to different processing conditions and working habits.Set wire controller's move speed freely.

Ø Record machining tracking information, to monitor machining during unmanned operation to ensure safety.

Ø Functions of interpolation of straight line and circular arc.

Ø 5 axis Control four axis simultaneous program.

Ø Function of taper processing

Ø Function of processing different top and bottom shape

Ø Functions of short circuit and wire-break handling

Ø Functions of memorizing when power was cut and auto-stop after processing

Ø Functions of auto-edge position and auto-centering

Ø Function of auto-adding transitional arc (Arbitrary angle)

Ø Function of processing backward

Ø Functions of menu technology and auto-programming

Ø Data transmission

Ø The remote controller allows for freely setting the moving speeds of each axis.

Ø Processing information tracking record, processing monitoring, ensuring safe operation when there is no one processing;

Ø Remote access system and remote control assistance (optional);

CNC hardware

Ø P4 Indutrial PC

Ø High resolution 17in large screen display

Ø The hand feeling of keyboard and mouse is excellent.

Hardware configuration

Ø XY axis AC servo motor

Ø UV axis stepper motor, optional servo motor

Ø Electric vertical movement along the Z-axis;

Ø Non-resistance power supply

Ø Electronic Handwheel Manual Controller

Ø USB and LAN data interfaces

Ø Centralized lubrication oil supply device

Ø Concealed circular LED working lighting, three-color working status indicator lights;

Ø Aluminum processing module (optional)

+86-13825734323

+86-13825734323

Message

Message