Item | Parameters | ||||||||

Machine body | ZNC320 | ZNC350 | ZNC430 | ZNC450 | ZNC540 | ZNC650 | ZNC750 | ||

The oil tank size | 800×520×330mm | 950×680×420mm | 1200×680×420mm | 1240×720×420mm | 1380×760×520mm | 1580×870×630mm | 1650×1100×630mm | ||

Worktable size (X*Y) | 500×300mm | 600×300mm | 650×350mm | 700×400mm | 850×450mm | 1000×550mm | 1100×600mm | ||

XY axis travel | 300×200mm | 350×250mm | 400×300mm | 450×350mm | 500×400mm | 600×500mm | 700×550mm | ||

Z axis travel | 200mm | 200mm | 200mm | 200mm | 300mm | 300mm | 350mm | ||

Spindle head stroke(Auto) | 180mm | 180mm | 200mm | 250mm | 200mm | 250mm | 250mm | ||

Max.distance from worktable to flat surface of electrode | 150-450mm | 200-500mm | 200-580mm | 220-660mm | 700mm | 800mm | 850mm | ||

Max. electrode wight | 50kg | 50kg | 80kg | 80kg | 100kg | 150kg | 150kg | ||

Max. workpiece size | 600×400×400mm | 750×400×400mm | 1050×650×560mm | 1050×650×560mm | 1150×600×560mm | 1350×800×600mm | 1700×920×720mm | ||

Max. workpiece weight | 150kg | 200kg | 800kg | 800kg | 1000kg | 1500kg | 2000kg | ||

Oil tank capacity | 200L | 200L | 430L | 430L | 550L | 820L | 1000L | ||

Oil tank dimension | 1000×1300×455mm | 1050×1300×455mm | 1400×500×550mm | 1050×650×560mm | 1150×750×560mm | 1350×800×600mm | 1700×920×720mm | ||

Machine weight | 1050KG | 1100KG | 1350 | 1450 | 1650Kg | 2000kg | 2900kg | ||

Out size | 1050×1350×2100mm | 1100×1350×2100mm | 1450×1250×2200mm | 1470×1350×2300mm | 1650×1460×2300mm | 1900×1680×2360mm | 2000×1710×2360mm | ||

Electrode consume | <0.2% | ||||||||

Tiptop surface roughness | 0.4μm | ||||||||

Power Supply | 3×380V ±10% ,50/60Hz | ||||||||

Max. working current | 50A | 75A | 100A | ||||||

Max.power | 4.5KVA | 7.5KVA | 10KVA | ||||||

Max. maching speed | 460mm³/min | 560mm³/min | 700mm³/min | ||||||

Control box weight | 220kg | 250kg | 280kg | ||||||

Control box dimension | 950×600×1850mm | 1020×650×1850mm | 1100×680×1850mm | ||||||

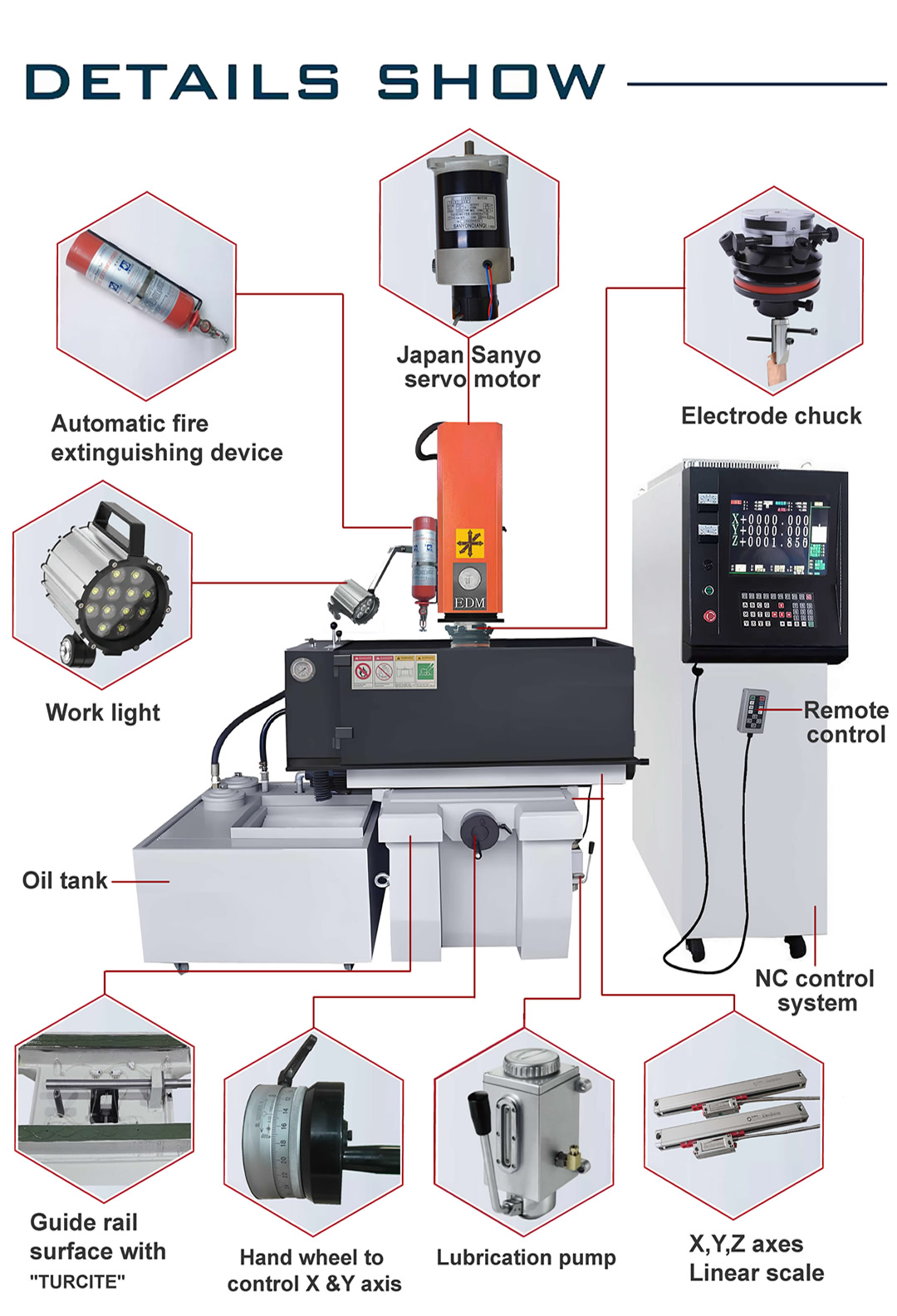

Mechanical Features

Ø CAD design and high-precision structure, FC-250 castings, precise material, strong toughness, tempered and natural weathered, durable and not easily deformed.

Ø X,Y axles adopt of Taiwan or the same level of ball screw

Ø The X and Y axis adopt the design of V-shaped matching plane side rail; the base, sliding table, pillar, and mandrel adopt good structure, which helps to maintain the highest precision of the equipment.

Ø The main shaft uses high-precision linear rails and ball screws to ensure high-precision performance.

Ø Adopting Japan SANYO FC servo motor.

Ø The work surface is high-frequency processed and precision ground, high hardness and not easy to wear.

Ø Using centrifugal high pressure oil pump and 10u filter system.

Ø Lubrication system uses recovery mode, rail lubrication action at once, and keep the look clean.

Ø Steady safety device, optical sensors, auto answer, fire extinguisher and power cut off.

Ø Three-axis 1µ grating ruler and three-axis fully closed circuit design are adopted to effectively improve the processing accuracy

Ø Can choose red oil, pumping oil slagging mode, but also choose not to dip the oil processing.

Controller characteristics

Ø 15-inch LCD computer display

Ø Adopts the industrial low-power motherboard, and VLSI ultra-large integrated circuit design, with powerful functions, stable performance and durability.

Ø Anti-oil and anti-pollution keyboard, longer service life and more durable.

Ø Operation panel: It can rotate 90 degrees and comes with a remote control. Easy to operate, convenient and fast to handle. Ensure the comfort of operators in the workplace.

Ø High Frequency Power and the Internal Circuit: The modular design is used in the internal wiring, Creative electric pulse machining with high efficiency. High quality, high precision, high efficiency. which can reduce the probability of the failure, and it's easy to maintain.

Ø Built-in graphite processing circuit: It can process large area, sharp shape, deep hole and thin sheet with a maximum processing efficiency of more than 2 times compared with the old model.

Ø Superhard alloy processing circuit: (optional)

Copper→tungsten steel: It can effectively control the electrode consumption and processing efficiency. The electrode consumption can be controlled below 5%, with faster and finer speed. The surface crack of tungsten steel is smaller, and polishing is easier.

ZNC System software operation function:

Ø The Chinese language/English operating system is simple and clear, easy to learn and use,Conversational man-machine interface, and also has the operation prompt function,convenient and practical.

Ø Provide 60 sets of files for storages.

Ø Preset 10 commonly used processing parameter memory modules,equipped with carbon deposit prevention system.

Ø Can automatically store the parameter position and reset the machine to zero without being affected by power failure.

Ø With ten-segment deep processing parameters from rough processing to fine processing.

Ø Program by oneself: You can program the processing conditions depends on your experience.

Ø AUTOZ programs automatically: Giving the biggest depth at the first of electric current and finished choosing thickness or thinness, AUTOZ would program the processing conditions.

Ø Intelligent programmed the conditions: only if choose the shape of electrode, the materials of both of electrode and work piece, the square of the electrode and choice size (thickness / thinness) of processed work piece when finished, the setting of depth, machine can program the processing conditions automatically.

Ø Adjust release electricity conditions automatically, when releasing electricity unsteadily, the computer would modify electricity efficiency and work time; releasing electricity will recover automatically when stead able. Revise the parameter during the working will not effect the machining.

Ø Supporting the edge finding ball function, automatic edge finding function, various processing parameters, power-off coordinate recording, the most complete functions, suitable for all kinds of simple/complex/multimode multi-cavity/deep hole.

Ø The machine has the function for ALLM, Infrared flame detection, alarm for finishing the depth and close the power.

Ø The controller has the function for changing the Plus-n-Minus, what’s it also has the function of reverse processing.

+86-13825734323

+86-13825734323

Message

Message